Spider Webs

Though spider webs may seem like delicate material, its UV-reflective properties and tensile strength make it resilient to many environmental stimuli.

Biomimetic Designs

Bird-Safe Windows:

It is estimated by the New YorkCity Audubon Society that approximately 100 million birds die every year due to collisions with buildings. To prevent against such deaths, Ornilux created windows that weave UV-reflective material throughout the glass, to make surfaces visible to birds, while remaining clear for human eyes. This is inspired by birds being able to avoid spider webs, due to the silk's UV-reflective properties.

Low-density Building Material:

Spider silk, though comparable to steel's tensile strength, is a considerable competitor to steel due to one major advantage: its low density. Spider silk is about six times less dense than steel, which causes its ratio of strength to density to far exceed the competition's. Its ratio of strength to flexibility also far exceeds that of Kevlar, which is the strongest synthetic fiber ever produced, used as a replacement for body armor in combat zones by militaries around the world. Though there are not yet biomimetic designs utilizing spider silk, it is an extremely attractive material for scientists and engineers, and holds endless potential as a building material.

The Science Behind Spider Webs

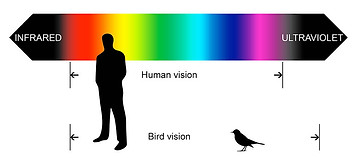

Birds' vision is essentially the same as human eyes with one main addition: the ability to see UV light. Spinning UV-reflective silk is then beneficial for spiders to prevent against bird flying through and destroying webs. Insects, on the other hand, while still able to detect UV light, have spatial resolution roughly 100 times poorer than that of humans. Given that most spider silk has a diameter of only about 2.5-4 μm, insects must then be within a millimeter to see the silk, at which point, it is probably too late to avoid being caught in the web.

As far as the strength of the silk, some varieties have been found to have a tensile strength just above 1 GPa (a unit of measuring force per unit are). That equates to a mid-range value for steel, where strengths range from 0.2 GPa to nearly 2 GPa. This is due primarily to its molecular composition, which uses beta-sheets to reinforce the hydrogen bonds within the silk's protein crystal. The protein structures are also responsible for the silk's flexibility, allowing it to stretch 140% before any breakage.

Spark your Imagination: Explore More Articles